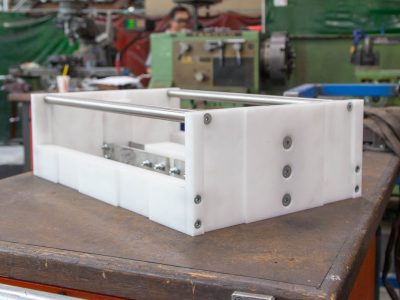

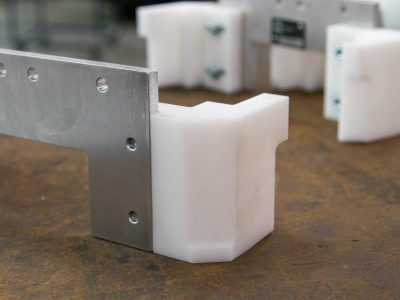

At Automaint Solutions, we understand that sometimes purchasing a new machine for a job is not something that is always possible and sometimes older machines do the job just fine, but might require a refresh to keep them operating in optimal condition. Our highly skilled technicians are able to strip down, identify problem parts and components that need replacing and then assemble and test the rebuild machine. During the rebuilding process we are also able to design and manufacture any additional parts to improve the operation of the machine.

Automaint Solutions has many years experience manufacturing custom tooling for almost all brands of tray erectors and the many quirks of operation depending on the tray being formed by the tray erector.